Sample preparation of material samples

- Engineering Center /

- Services

The Engineering Center "High Temperature Composite Materials" provides services for sample preparation and various materials microstructure research in the city of Korolev.

Sample preparation is a set of actions on the object analysis to prepare it for the subsequent metallographic analysis , i.e. the sample cutting and polishing.

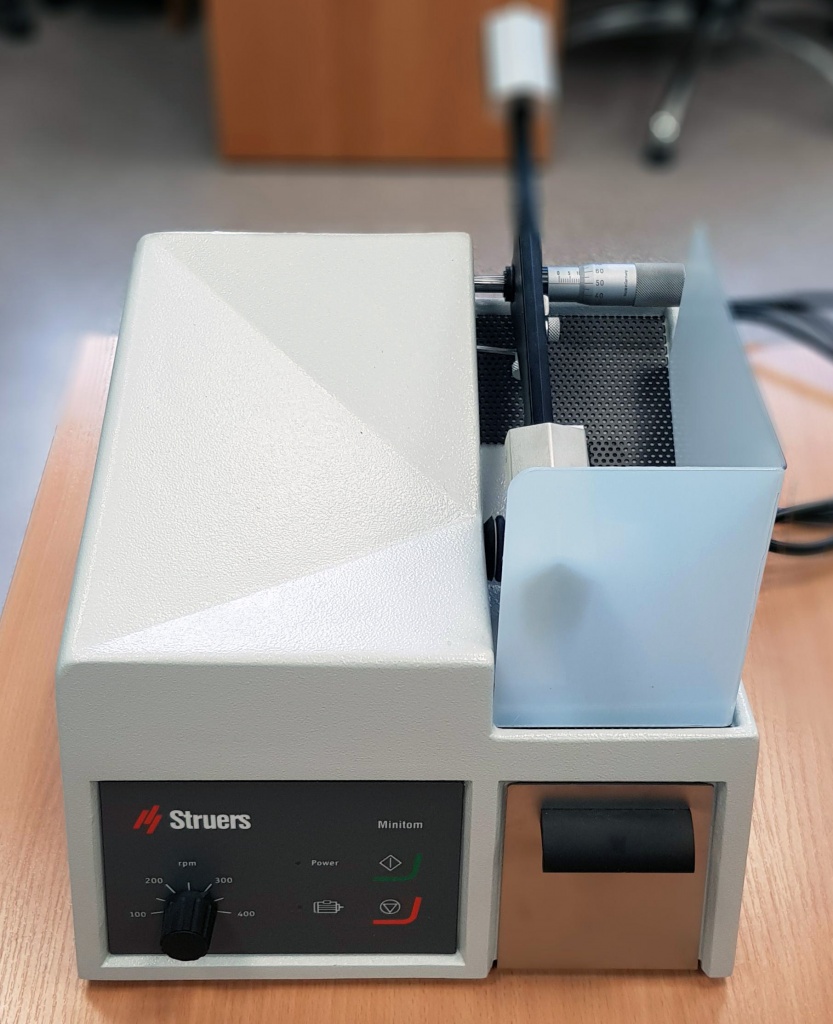

1. Automatic high precision low speed cutting machine Minitom for cutting all types of materials.

The maximum sample size - 30 mm in cross section. The required sample size can be set with an accuracy of ± 0.01 mm using a micrometer screw, and the pressing force when cutting can be selected depending on the sample weight . The cutting speed is continuously variable, the motor is designed to ensure the constancy of the selected speed at any load.

Technical characteristics:

- cutting disc diameter 127 mm;

- rotation speed - 100-420 rpm;

- max. sample diameter - 30 mm;

- max. sample cross section 30x30 mm;

- cutting with cooling;

- precision.

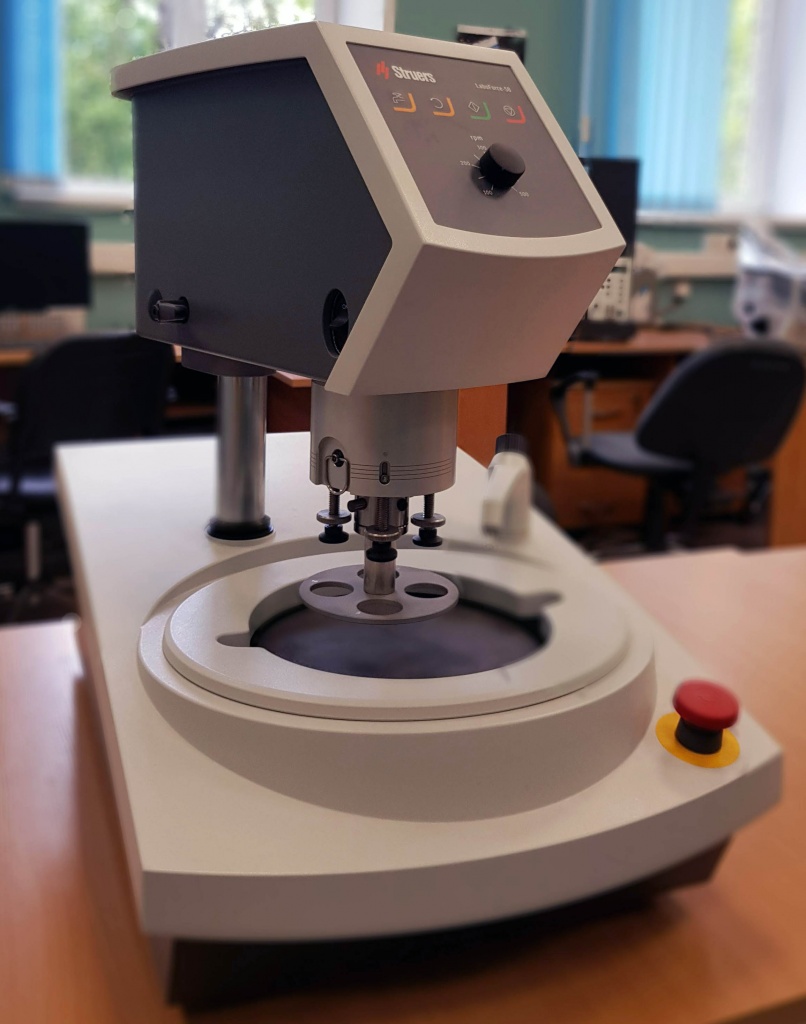

2. Automatic grinding and polishing machine LaboPol with a semi-automatic rotator of 1–4 single samples.

Designed for quick sample preparation in the laboratory or near the production line. Reliability in operation and speed in work provides the ability to prepare the samples quickly and efficiently - 24 hours 7 days a week.

Technical characteristics:

- disc diameter 200 mm;

- operating mode - semi-automatic;

- the number of samples per shift - up to 60;

- load on the sample / board maximum - 30 N;

- rotation speed - 50-500 rpm.

Equipment for studying the materials microstructure has two inverted metallographic microscopes.

1.Research-grade inverted metallographic microscope Olympus GX-51 with SIAMS 700 imaging system.

Designed for optical studies, with direct illumination in reflected light of the various materials samples microstructure , including composites based on carbon and other types of fibers.

Thanks to the visualization system, consisting of a digital camera and SIAMS 700 software, almost all well-known methods for studying thin sections of metals and other preparations and metallographic analysis are implemented. SIAMS 700 software is designed to automate metallographic analysis with the aim of assessing product quality and materials input control in accordance with the requirements of Russian and foreign standards.

Magnification: 5x; 10x; 20x; 50x; 100x.

2. Metallographic inverted microscope with a digital camera Altami MET 1C.

The metallographic digital complex Altami MET 1C is designed to study the composites, metals and alloys microstructure in reflected light in a bright field under direct illumination. The presence of a camera makes it possible to obtain high-quality digital images, display them on a computer screen, process and evaluate them using image analysis programs.

Magnification: 5x; 10x; 20x; 50x; 100x.

To order services for sample preparation or microstructure research in the city of Korolev, please submit your application and our specialists will contact you to clarify all the details during the day.